Synthace transforms miniaturized gradient elution workflows

What is gradient elution?

Gradient elution is a liquid chromatography technique where the strength of the mobile phase gradually increases. This is typically achieved by increasing the mixing ratio of two buffers, Buffer A and Buffer B. Both linear gradients (continuous change) or stepwise gradients (discrete intervals) can be used. When running gradient elution with automated liquid handlers and miniaturized columns, a stepwise gradient must be used, since such devices don’t allow a continuous flow of buffers.

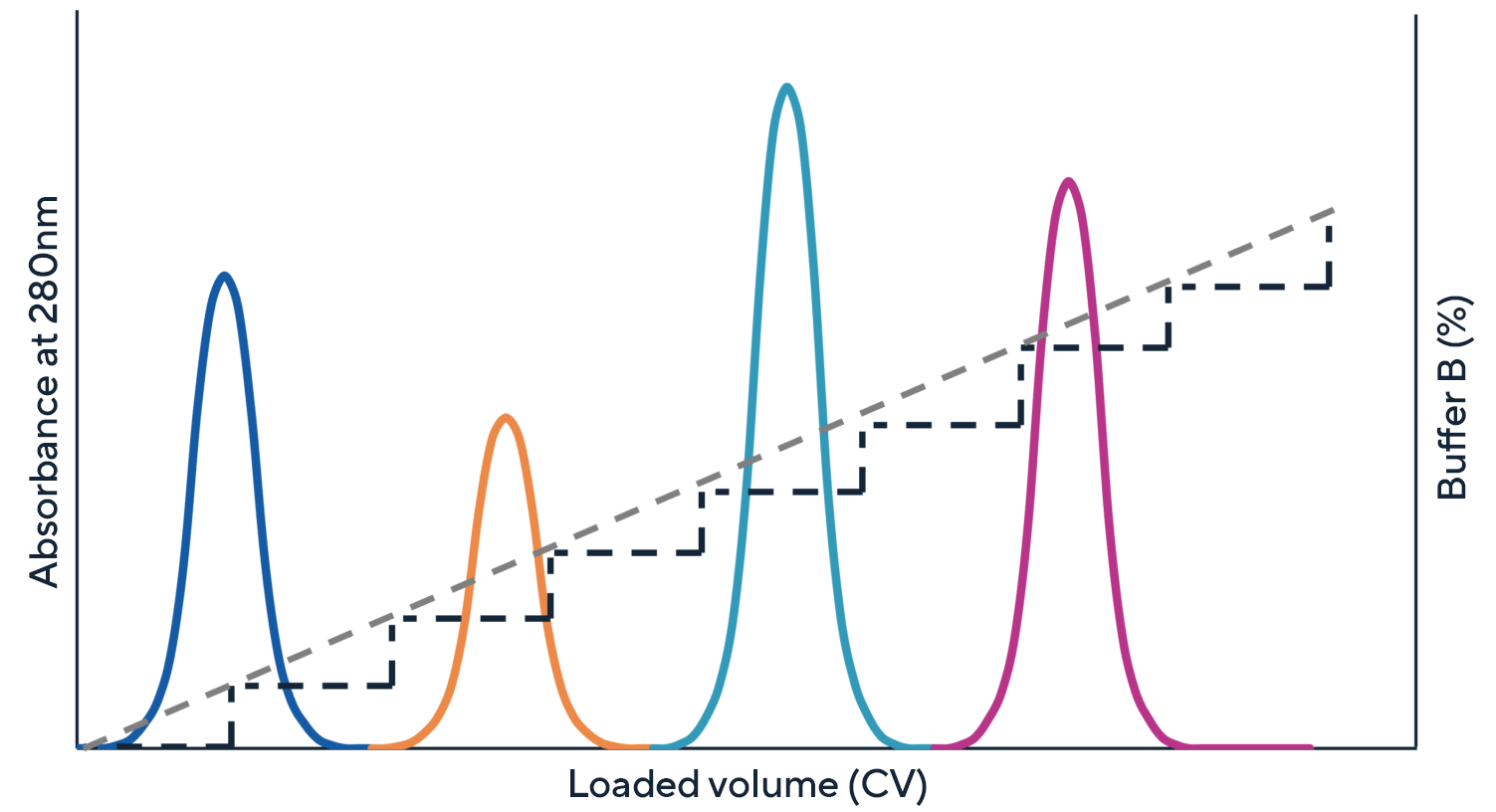

The goal of gradient elution is to separate individual compounds in a sample. Protein quantity is typically measured using absorbance at 280nm. Because different compounds elute at different Buffer B concentrations, we expect to see individual absorbance peaks in the resulting chromatogram.

A gradient elution chromatogram showing absorbance peaks of eluted compounds as well as linear (grey dashed line) and stepwise (black dashed line) buffer gradients. Absorbance measurements are normally reported on the left Y-axis, while Buffer B concentration is normally reported on the right Y-axis.

What are the benefits and challenges of miniaturized gradient elution chromatography?

Miniature chromatography columns require smaller sample volumes and enable parallelization of purification conditions, leading to shorter process development timelines at lower costs. However, there are challenges associated with scaling down the purification process onto a liquid handler.

Since miniaturized gradient elution is performed with automated liquid handlers, a stepwise gradient must be used. To make the gradient appear more linear (pseudolinear) the number of steps within the gradient needs to be increased. Since each step has an individual Buffer A : Buffer B ratio, this also increases the number of different buffers that need to be made. As a result, programming liquid handling robots to create such buffer gradients is often a tedious and cumbersome process.

The amount of protein in each step of the gradient elution is often quantified by using UV absorbance at 280nm. Carefully aligning such absorbance data from a plate reader to the correct fractions from each chromatography column, and corresponding Buffer A : Buffer B ratio, can be another challenge. This process is often done manually with tools like Excel®, which makes the task time-consuming, error-prone, and often inflexible.

Because UV absorbance measures non-specific protein information only, elution fractions are frequently further analyzed using electrophoresis or high-performance liquid chromatography (HPLC) to obtain specific protein information. Cherry-picking fractions for such downstream analyses often requires designing a follow-up script or worklist, which is cumbersome and tedious. In addition, combining such downstream datasets with the parameters of the original experiment to obtain a complete story is often an arduous, error-prone task that delays time to insight.

How to instantly improve your gradient elution chromatography for miniaturized protein separation

At Synthace we believe that scientists will benefit from a comprehensive, user-friendly software solution to enable automated, end-to-end gradient elution chromatography for miniaturized separation. Synthace was developed with the scientist’s needs in mind: a powerful cloud-based software platform providing a unified, visual interface that enables gapless automation of gradient elution workflows. Synthace streamlines experimental design, experiment execution and data aggregation, normalization and visualization.

In a recent online demo, our Head of Scientific Solutions, Luke Cach, demonstrated how we leveraged Synthace with the Tecan Te-Chrom™ system and Repligen OPUS® RoboColumns® in our own lab to separate a mixture of four proteins using a 60-step gradient elution after identifying a set of initial separation conditions. We could easily cherry-pick samples for downstream purity analysis using electrophoresis with PerkinElmer’s LabChip® GXII. The resulting data was automatically combined with the chromatograms auto-generated during the gradient elution runs.

Watch the demo to find out three ways to instantly transform your miniaturized separation workflows with Synthace (summary below).

1. Easy experimental setup and pain-free protocol modifications

Synthace allows you to easily create workflows for sophisticated gradient elution runs using its graphical user interface, where you specify your samples, materials, and parameters for each chromatography stage, such as the number of gradient steps, the volume per step and the desired end concentration of Buffer B. It then translates the workflows to instructions for your liquid handler and plate reader, prompting them to execute the experiment. You can modify your workflows with a few simple clicks (no scripting needed) and perform multiple iterations of your experiment with ease.

You can also simulate and preview your workflows in silico from your home office, and verify and validate the generated instructions. This is particularly beneficial when lab access is limited. Once validated, workflows can be scheduled for execution in the lab.

2. Automatically calculated and prepared buffer series for gradient elution

When building the gradient elution portion of your workflow, simply specify your stock solutions and any desired parameters (number of fractions, starting and final Buffer B percentage, volume per fraction), and Synthace auto-calculates how to create your buffer series. Synthace calculates how much volume of each buffer you need and instructs the liquid handler to prepare the required buffer series. During our in-house protocol validation, Synthace auto-calculated and prepared each buffer for a 60-step gradient.

3. Automatic alignment of LabChip purity data with auto-generated chromatograms

Synthace sends the eluted fractions to the plate reader for absorbance measurements and then automatically aligns the resulting plate reader data with the appropriate fractions collected during the chromatography run. The software keeps track of all experimental data and metadata and automatically compiles both raw and path length and/or blank-corrected chromatograms. There is no need to manually wrangle data or generate visualizations.

Further, Synthace allows you to easily cherry-pick fractions for downstream analyses, such as measuring the purity of your separated compounds with LabChip. The resulting purity data is imported into Synthace, where it is automatically aligned with the chromatograms for a complete and structured dataset. The dataset can also be downloaded in common formats and used within external analysis software.

Other posts you might be interested in

View All PostsDynamic Binding Capacity with Synthace and Tecan Te-Chrom™

Miniaturized Purification with Synthace and Tecan Te-Chrom™: Uniting Robust Execution With Flexible Planning and Comprehensive Data Analysis

Synthace just got a whole lot better: 4 improvements biologists need to hear about