DOE for media

optimization

Run DOE workflows for media optimization and keep track of complex liquid combinations throughout the entire process.

Request a Demo Take a tour

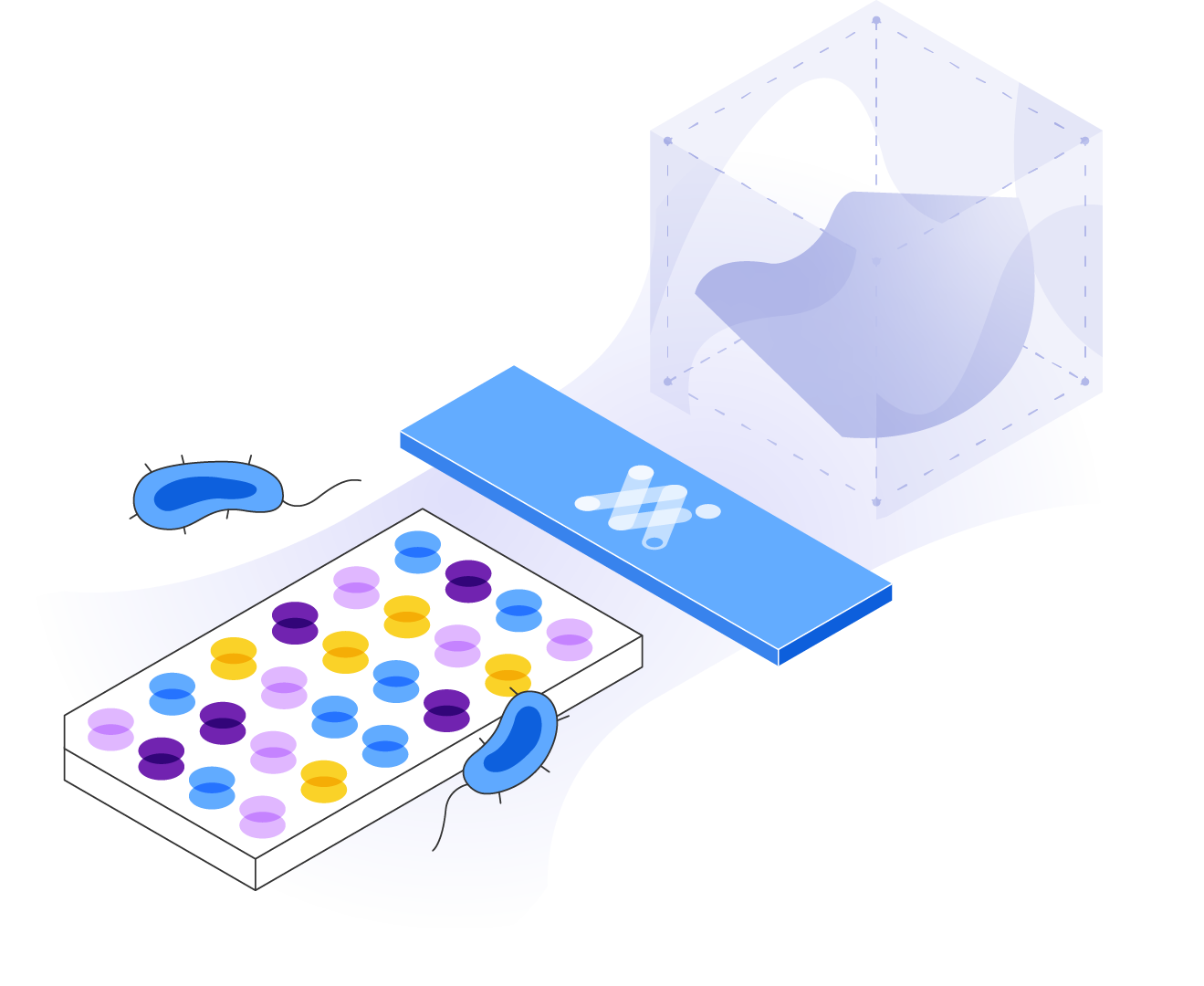

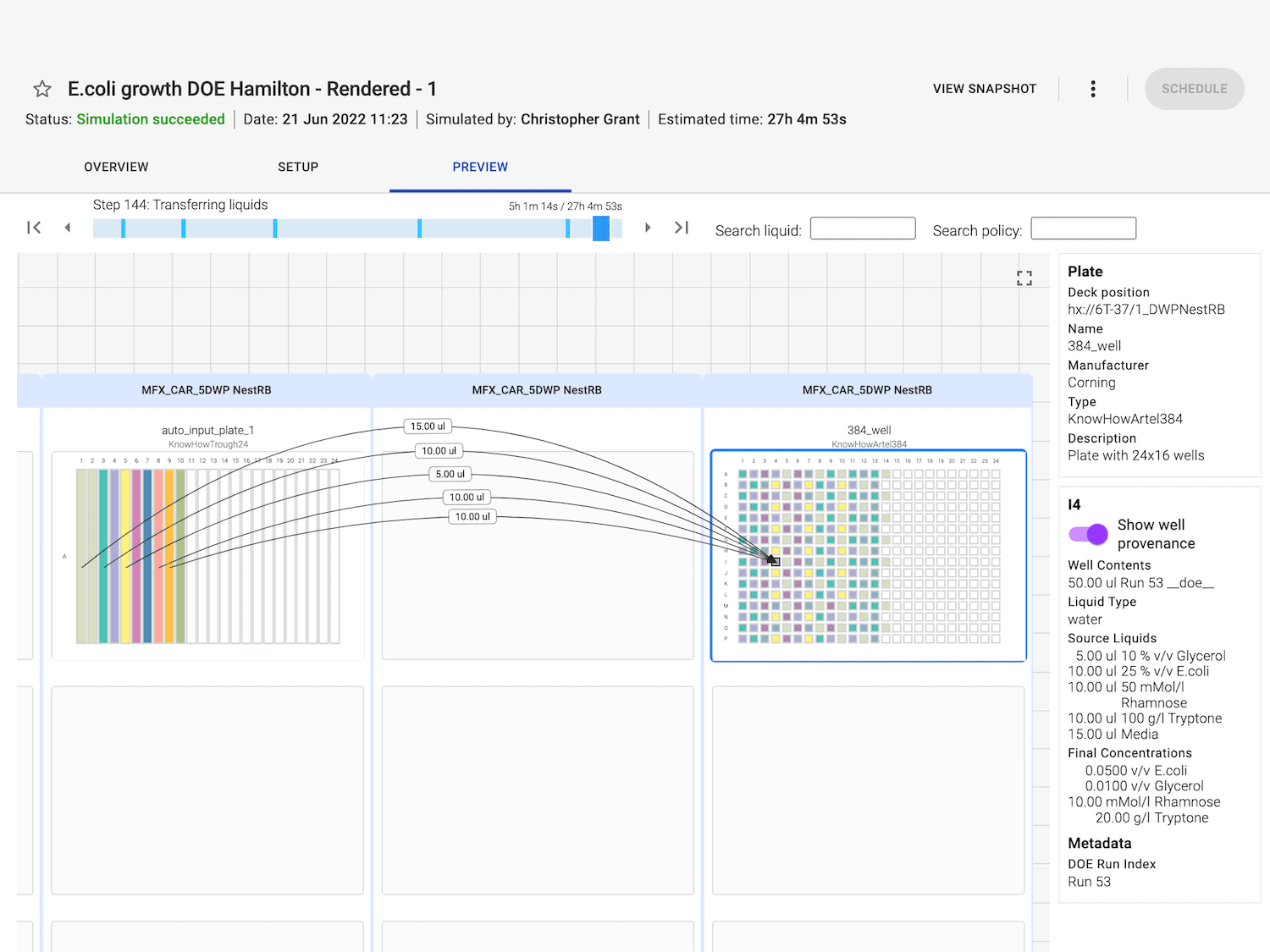

Generate automation instructions from your design, automatically

Whether built or imported, Synthace translates your DOE designs into highly accurate liquid handling steps for you.

There’s no need for complex manual coding—you can build and upload designs in Synthace to automate your workflow.

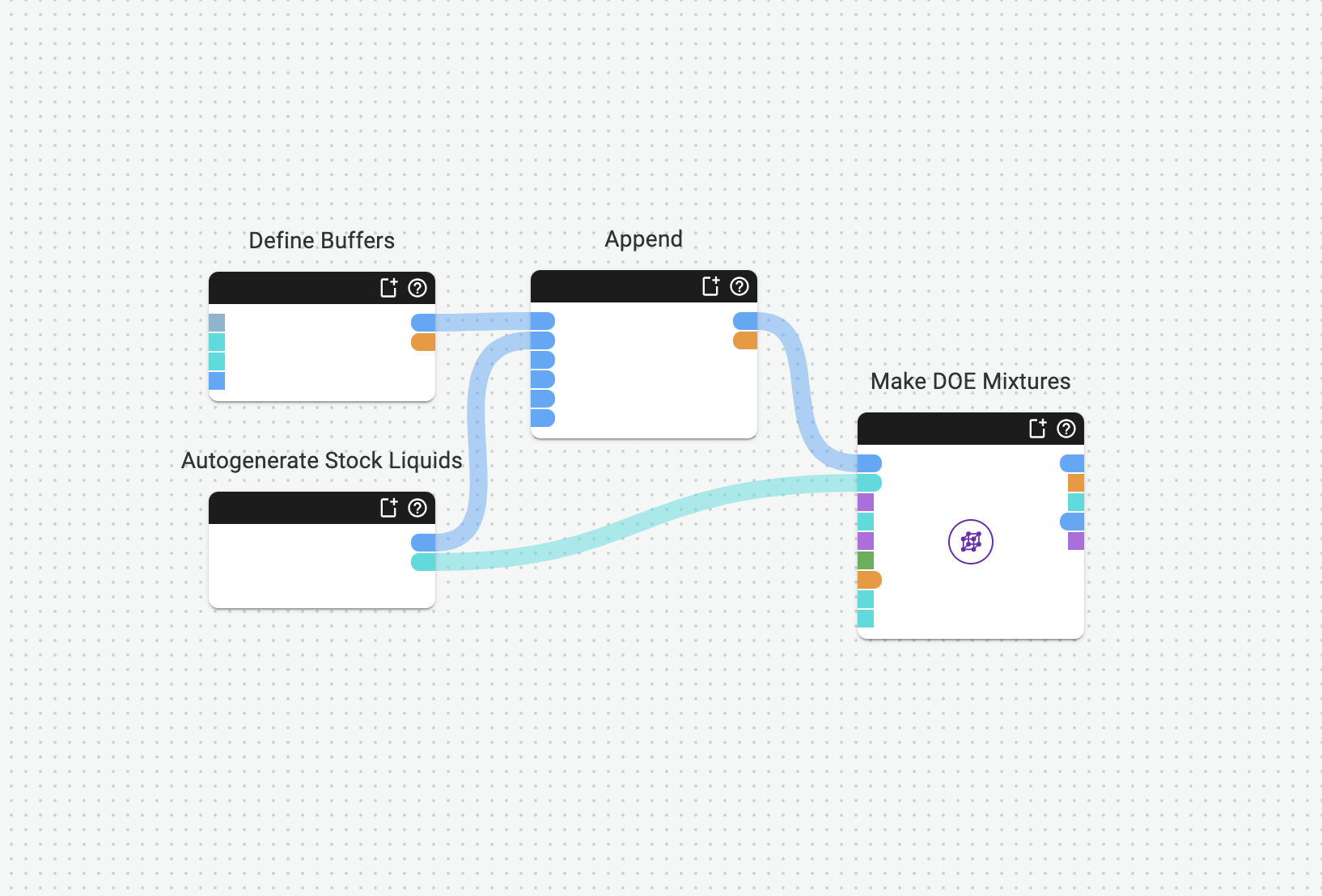

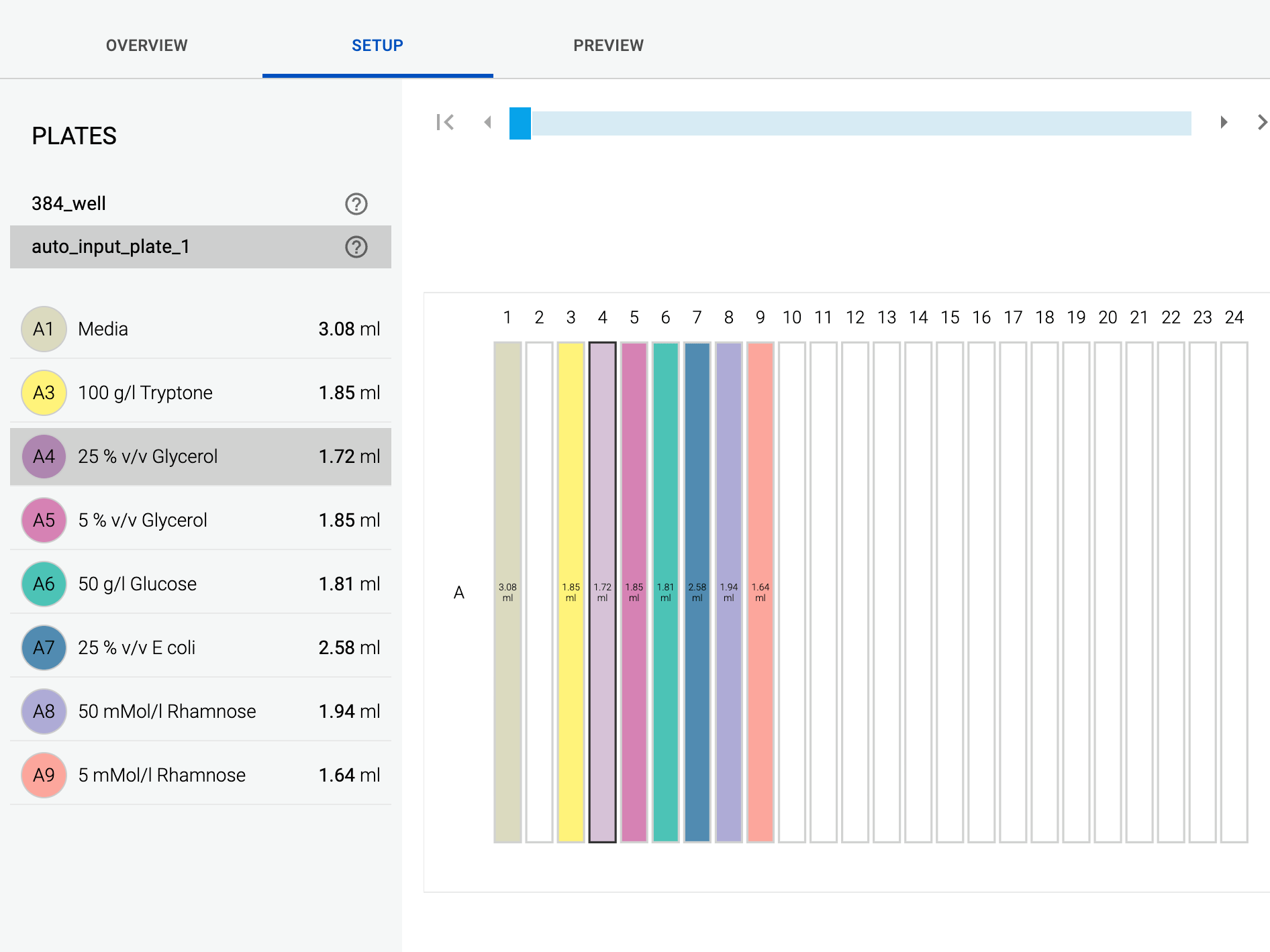

Define, tag, and trace all your liquids

Tracking liquids can be time-consuming and difficult, even at the best of times.

Synthace lets you define them and tag components and subcomponents with rich metadata.

Even during the most complex DOE workflow, you’ll know exactly what’s in each well and where it came from.

Check final well concentrations in advance

Even with trial runs, it can be difficult to know if your manual or automated protocols will result in the final well concentrations you’re looking for in your DOE run.

Synthace lets you preview all of this in your browser before setting foot in the lab, so you can be confident before you even get started.

Generate automatic stock allocations

Uncertain what you’ll be putting on your liquid handler deck, or have a constrained stock concentration?

Synthace DOE calculates this for you based on your DOE design, meaning you can preview everything in advance to make planning easier.

“In just a few months Synthace DOE saved me from performing 20,000 manual calculations—it’s all done for me.”

Alex Rimmer | Stem Cell Scientist III, Uncommon

Intel from our DOE experts

View All PostsMeet Thierry Dorval, Head of Data Science and Management at Servier

Meet Dan Thomas, CEO & Founding Consultant at Twenty24 Consulting

Meet Roxana Redis, Associate Science Director at Charles River Laboratories