Syngenta + Synthace

Building adaptable, scalable experimental workflows

Syngenta's Biologicals team have unlocked the power of lab automation, providing both the a biological language for expressing automation needs, and a tool to visualize the outcomes without setting foot inside the lab.

Tour the workflow builder Request a DemoAt a glance:

- Increased automation utilization across the Biologicals team

- Cut weeks of work to days

- Dramatically accelerated development time

Overview

Syngenta is a world leading agricultural company that develops novel solutions to support farmers worldwide, helping them feed the planet and enabling them to establish sustainable, safe, and consistent agricultural practices.

Scientific research forms the foundation of Syngenta, employing 5000+ scientists across chemistry, chemical engineering, biochemistry, and biology. The Biologicals Group at Syngenta develops proteins for use as biological control agents and for regulatory testing of novel chemistries.

Challenge

Syngenta was looking to improve their use of automation, and methods to make their protein production process more reproducible. Their core challenges included:

- Low uptake of automation across the Biologicals team

- Time-consuming processes for refactoring complex liquid handler scripts

- Insufficient traceability and reproducibility of experiments and data analyses

These proteins are often diverse and challenging to produce, highlighting the need for a more flexible, adaptable, and rapid approach to their production.

Solution

Working with Synthace, Syngenta's Biologicals team have unlocked the power of lab automation, providing both the a biological language for expressing automation needs, and a tool to visualize the outcomes without setting foot inside the lab.

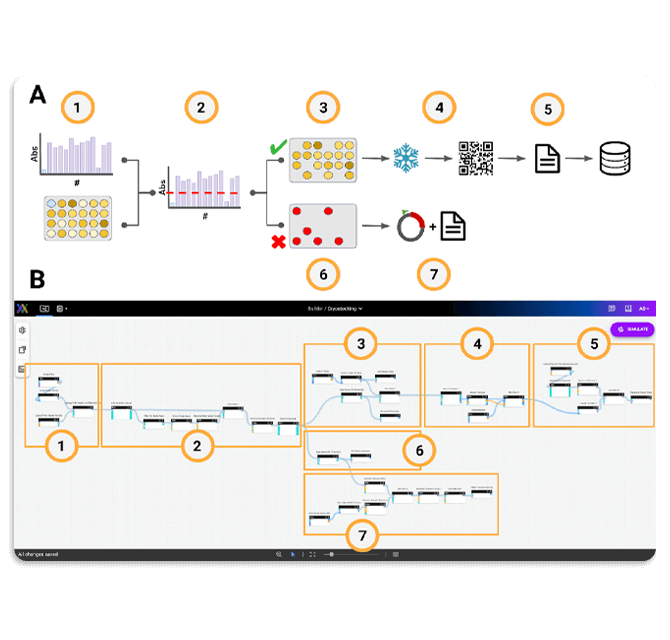

The team used Synthace’s no-code and device-agnostic Core Elements as building blocks to construct an automated bacterial transformation pipeline, and by automating routine data processing. The Synthace platform reduces manual data wrangling, giving their scientists more time to focus on more critical and sophisticated tasks.

Results

The Synthace platform has helped Syngenta achieve many drastic improvements to the accessibility, flexibility, and scalability of the Biologicals Group’s automation solutions.

Syngenta’s scientists are now empowered to focus on the science rather than spending hours and days working out practical details for experimental execution and manual handling of experimental data.

- End-to-end bacterial transformation and cryo preparation

- Processed data being used to prompt different experimental paths

- Variability of experimental process dependent on success or failure of transformation process

- Unlocked power of lab automation for scientists across the team

- Rapid iteration of automated workflows, in the office or remotely

- Automatic capture, process and store experimental results and metadata