CSL + Synthace

Transforming automated micro-purification experiments

CSL’s Purification Team in Parkville has more time to focus on science, rather than spending hours working out practical details for experimental execution and manually handling experimental data.

Tour the workflow builder Request a Demo

At a glance:

- Automated end-to-end micro-scale purification experiments on the Tecan Evo

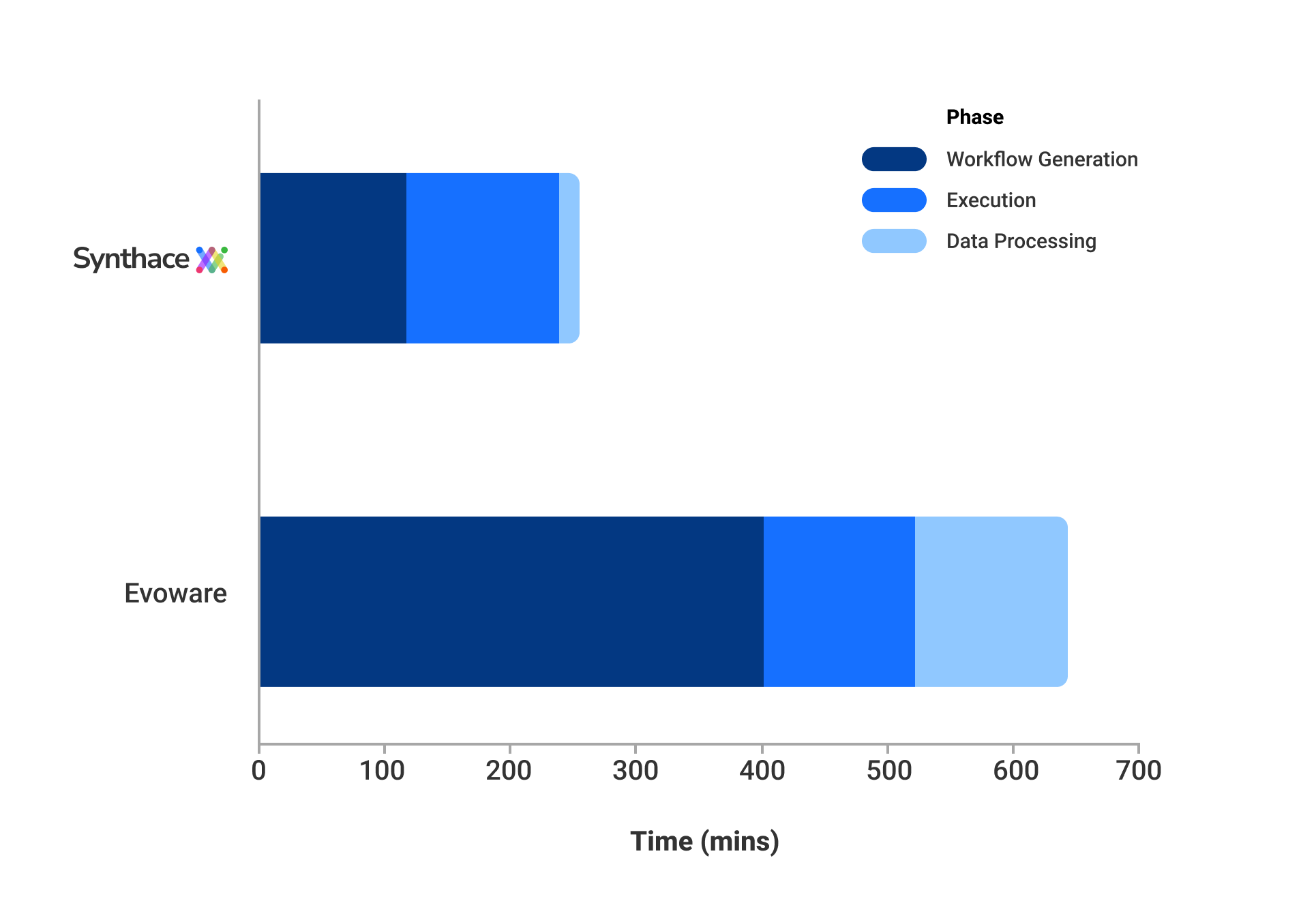

- Dramatic time savings compared to Evoware

- Higher device utilization and increased automation usage

Challenges

Low uptake of automation and

low device utilization (Tecan Evo)

CSL was looking for a solution that would enable scientists to plan and execute micro-scale purification experiments without the need to write code, ensuring their scientists could increase their throughput while improving the quality of their results.

Their core challenges included:

- Low uptake of automation caused by the need for complicated scripting

- Low device utilization in lab environments

- Visibility of experimental planning, executions and data

In addition, scripts to perform actions on their automation platform were not easily transferred between different sites.

Solution

The collaboration between CSL and Synthace aligned with the CSL Purification Team's goal of digital connectivity, robotics, and automation to improve process development efficiencies.

The drag-and-drop design elements of Workflow Builder translate their human-language directions into complex robot instructions with no custom scripting required.

The reduction in manual processing eliminates the chance of error and miscalculation which was of the utmost importance to the CSL Purification Team - since an experiment is only as valuable as the accuracy of its results.

Results

Using Synthace, CSL’s Purification Team realized significant time savings in the automation of end-to-end micro-scale purification experiments on the Tecan Evo liquid-handling platform.

These time savings, coupled with Synthace’s no-code interface, not only increased automation usage and throughput within the lab but also enabled the design of increasingly complex workflows by less experienced team members.

Through their Synthace partnership, CSL has experienced significant improvements to the accessibility, flexibility, and scalability of the Purification Team’s process development capacity.

CSL’s Purification Team in Parkville has more time to focus on science, rather than spending hours working out practical details for experimental execution and manually handling experimental data.

"A technology game-changer for usability."

"Synthace is a technology game-changer for useability... It allows the creation of complex workflows that I normally wouldn't have explored."

"The simulation functionality increases our confidence about the success of a run - before we run it."

CSL Purification Team

Parkville, Australia

About CSL

CSL is a leading global biotechnology company with a dynamic portfolio of lifesaving medicines, including those that treat hemophilia and immune deficiencies, vaccines to prevent influenza, and therapies in iron deficiency, dialysis, and nephrology.

Since its beginnings in 1916, CSL has been driven by its promise to save lives using the latest technologies. Today, CSL – including its three businesses, CSL Behring, CSL Seqirus, and CSL Vifor – provides lifesaving products to patients in more than 100 countries and employs 30,000 people.