Radically faster purification

process development.

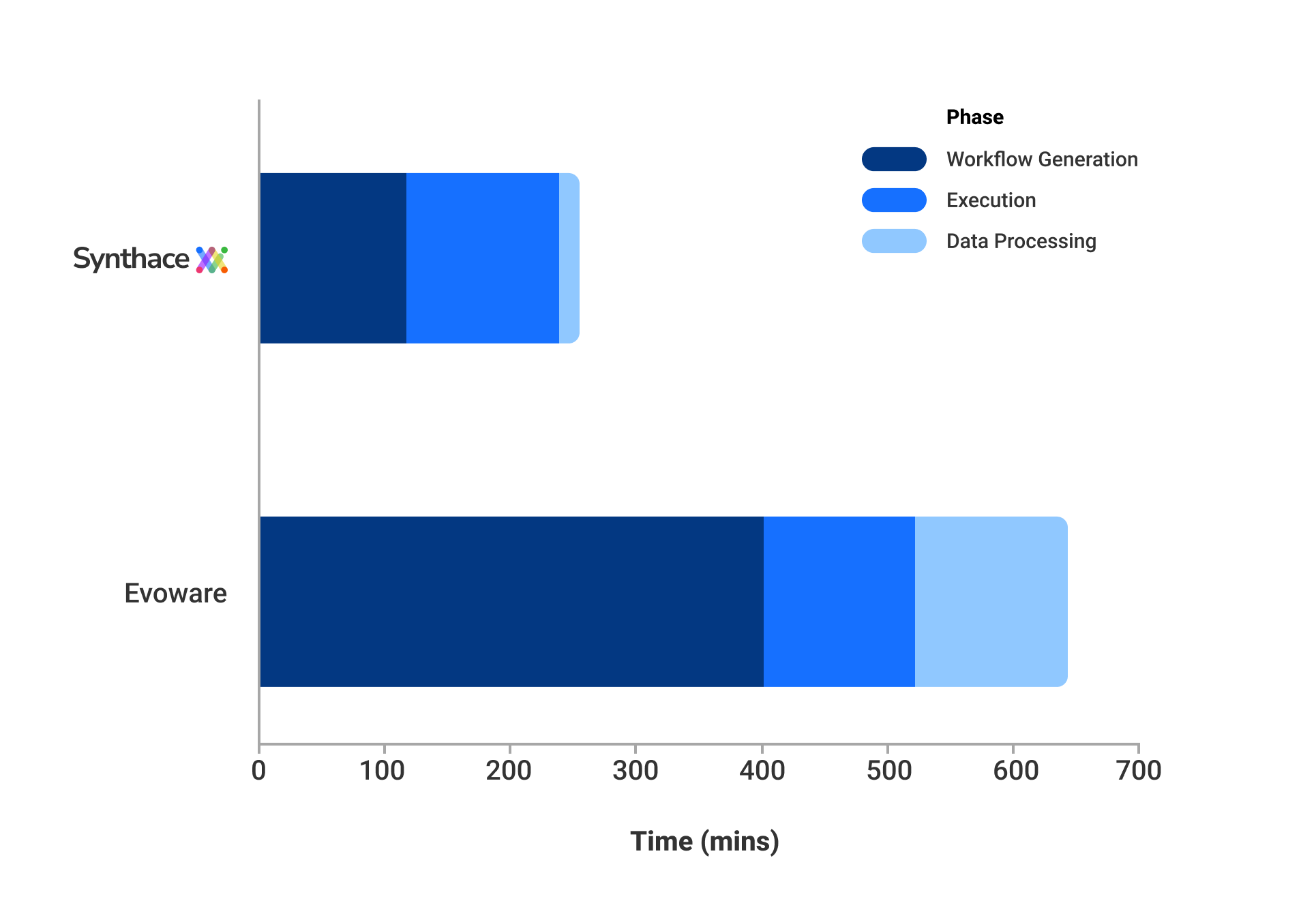

Get more reliable insights from automated, high throughput purification experiments 7x faster with Synthace—by simplifying protocols on the Tecan Fluent and Evo.

Request a Demo Take a tour

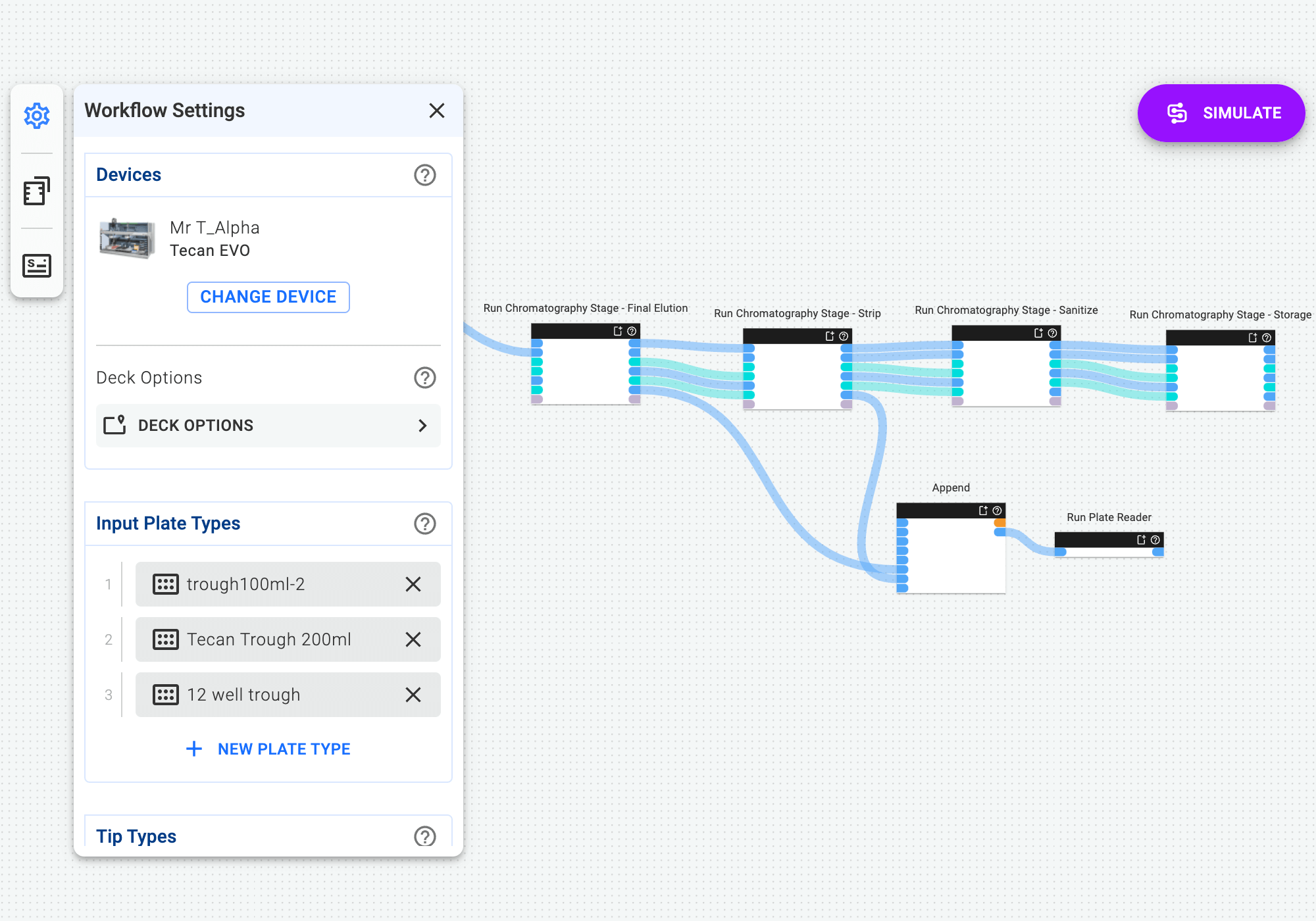

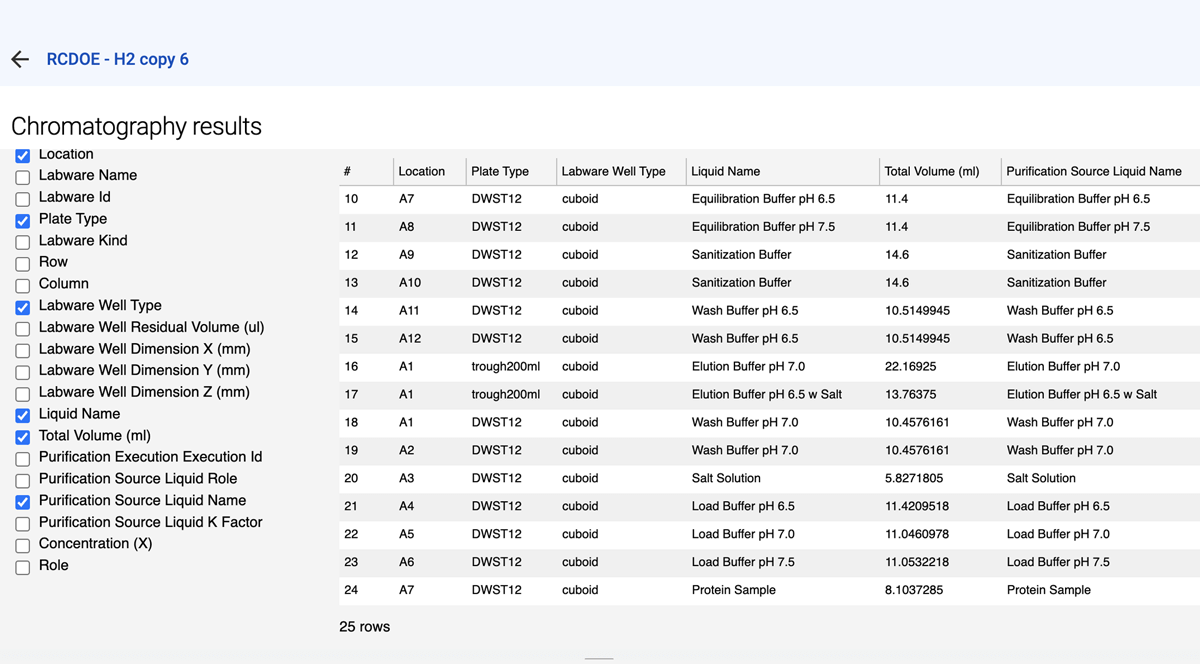

Smarter and faster than spreadsheets.

Free up time and headspace by describing your experiment with our drag-and-drop workflow, and simulating it to check it will run as planned. Synthace keeps track of the planning and calculations for you.

Experiment execution, your way.

Skip the months of device-programming training and pains of rigid scripting. Run your ideal plate- and column-based chromatography experiments with click-to-run automation.

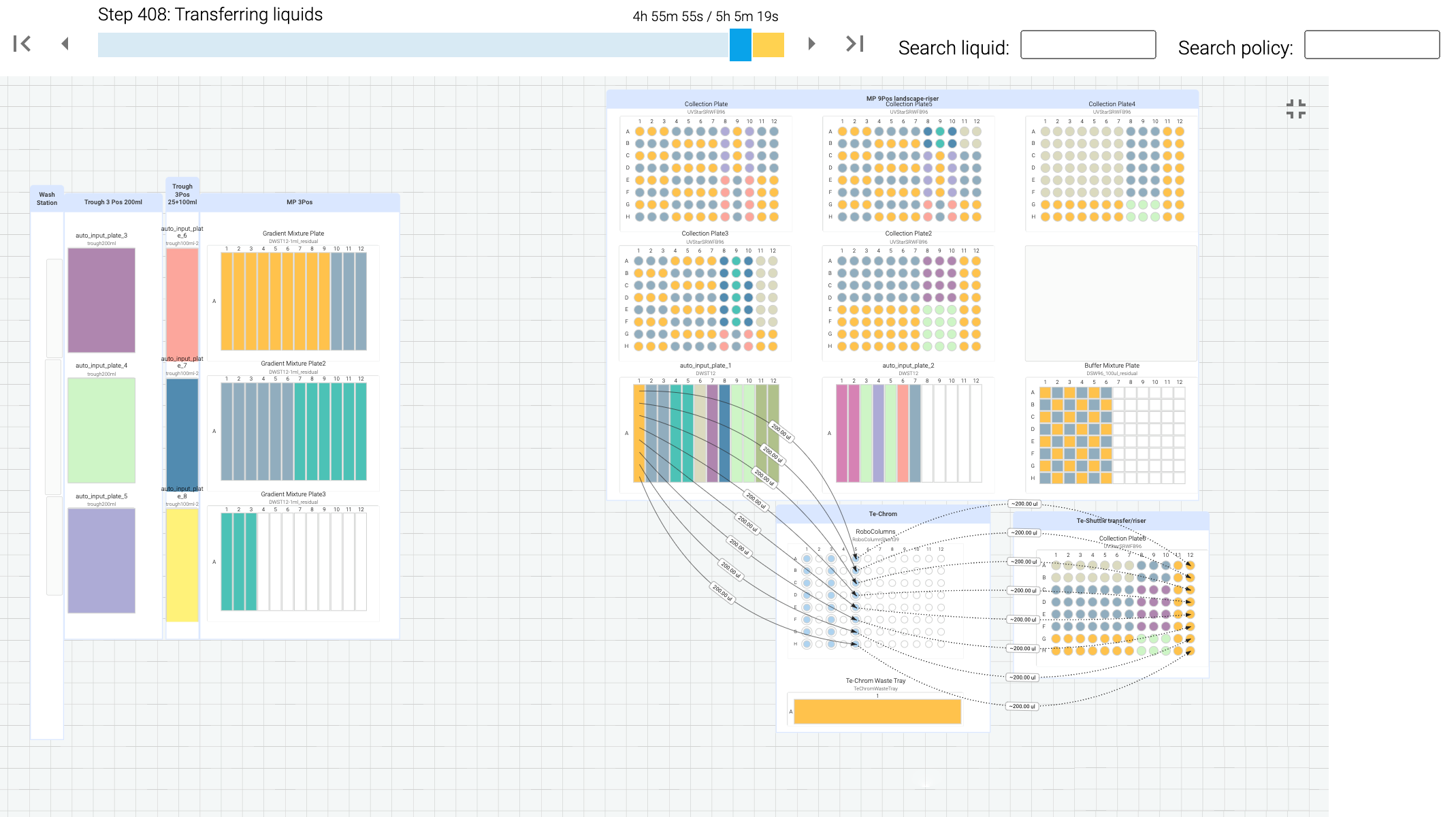

Instant, zero-code automation instructions.

Generate automation instructions for your chromatography experiments on the Tecan Fluent and Evo based on your experiment description. No more programming bottlenecks. Click “Run,” and watch your experiment come to life.

Easy, consistent method transfer.

Only create your method once. Then, increase throughput and validate your findings with confidence. Run the same method on any instrument, in any location.

CSL spent 60% less time on end-to-end micro-scale purification workflows.

"Synthace is a game-changer for useability. It allows the creation of complex workflows that I normally wouldn't have explored.”

CSL Purification Team

Parkville, Australia

Best Devices for

Purification process development

We integrate with a variety of lab setups, but these are the ones we recommend for miniaturized purification experiments.

It makes more complex workflows effortless, and the embedded Pathfinder optimizes robotic arm travel, streamlining your run.

It makes more complex workflows effortless, and the embedded Pathfinder optimizes robotic arm travel, streamlining your run.

Its flexibility adapts to your unique workflow, with easy plate creation, high precision, and robustness, ensuring reliable results and user-friendly operation.

Its flexibility adapts to your unique workflow, with easy plate creation, high precision, and robustness, ensuring reliable results and user-friendly operation.

It makes more complex workflows effortless, and the embedded Pathfinder optimizes robotic arm travel, streamlining your run.

Its flexibility adapts to your unique workflow, with easy plate creation, high precision, and robustness, ensuring reliable results and user-friendly operation.

From our blog

View All PostsMeet Thierry Dorval, Head of Data Science and Management at Servier

Meet Dan Thomas, CEO & Founding Consultant at Twenty24 Consulting

Meet Roxana Redis, Associate Science Director at Charles River Laboratories