How to Make High Throughput Design of Experiments the Norm in Assay Development

You’ve heard of "the lab of the future", but what about the experiment of the future? In some ways, it’s already here. For example, imagine setting up and running a space-filling, high throughput Design of Experiments (DOE) with:

- 6 factors of interest

- 384 different conditions to test

- 3,456 total runs

- 20,745 liquid handling steps

- An automatically structured dataset

Now imagine this: you can do it all in a single day. How is that even possible?

With the right combination of hardware and software, it’s easier than you think. In this article, we’ll look at what you’ll need to make this happen, and consider what this means for the future of assay development.

At the end of this article, we also have details about a live webinar where you can learn directly from two industry-leading experts in this space.

Rapid Discovery Powered by Design of Experiments on SPT Labtech’s dragonfly Dispenser

For assay development groups working in drug discovery, two questions dominate: how fast can we develop complex new assays, and how quickly can we transfer the winners into high throughput campaigns? For many, DOE is an obvious tool to help solve these problems. But that’s easier said than done. It’s hard enough to develop new assays at the best of times, even without DOE. But without the right mix of hardware and software? It can be grueling:

- Manual calculations take time and can be error-prone

- Complex liquid handling steps need custom code to execute

- Data collection takes a long time

- Data aggregation and structuring can be awkward and difficult

One of the dragonfly's positive displacement tips at work

Running through a manual DOE can sometimes take weeks or even months. But if we were able to do all of the above with accuracy, confidence, and in a fraction of the time, the hours and money saved could be plowed straight back into even more iterations.

Many have tried throwing more equipment, more people, and more consulting at this problem… with only marginal gains at enormous cost. So how do you push the boundaries of what’s possible without breaking the bank?

SPT Labtech’s Dragonfly and the Synthace Platform

For Dr. Anne Hammerstein, her mission has long been to give scientists the tools they need to accelerate their work. “I’m a scientist by training,” said Anne in a recent call we had, “but I ended up developing tools that make scientists’ lives easier.” In her time at SPT Labtech, the truest example of this is the development of the dragonfly discovery.

Originally conceived as a tool for crystallographers, their flagship dispenser immediately caught the eye of assay development groups. It’s not hard to see why:

- Lets you use 96, 384, and 1,536-well plates for simple method-transfer to high throughput workflows

- Uses positive displacement for low volume accuracy

- Makes no contact with liquid, so no time lost to tip replacement

When one of Anne’s customers approached her and said, “look, we're playing with JMP [the statistical modeling tool], and we'd love to implement it using your technology,” the next step was obvious: find a partner that could help make DOE a reality on their hardware.

That’s where Synthace comes in.

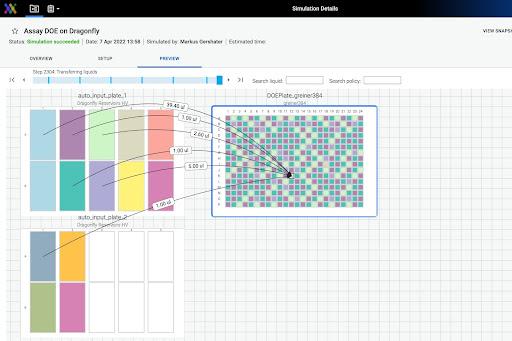

The Synthace platform shows the provenance of liquid contents in a 384-well target

How Synthace Translates Multifactorial DOEs Into Liquid Handling Steps for the dragonfly

“Yes, you can use JMP,” says Anne, “but JMP doesn't talk to the dragonfly.” And there’s the rub: you may have all your factors and levels figured out, but translating a multifactorial method into automated liquid handling steps is a whole other ballgame. So is aggregating your data afterward. For some, the first thing that comes to mind is: “how do I even code for that? How long will that take?”

The experiment of the future needs no custom code. Instead, there’s a platform that handles it for you. A platform, says Anne, that “translates what comes out of JMP so the dragonfly knows what to do. But even more important, one that structures that data back into JMP for the next iteration.” With high throughput design of experiments, the data output is just as important as the automation and design input to begin with.

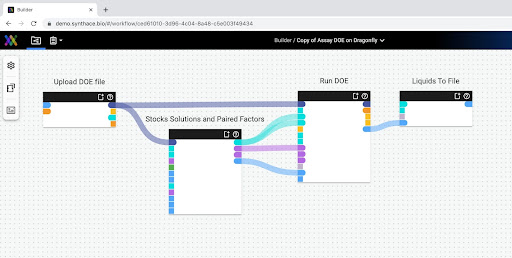

The high throughput Design of Experiments method built in the Synthace platform

So what does the Synthace platform actually do? You start by describing your method with drag and drop elements, then plug in your DOE design file from JMP. Once you’re ready to run, Synthace executes it for you on the dragonfly. To make it happen, Synthace does a lot of heavy lifting under the hood:

- Turns DOE files into optimized, automated liquid handling steps

- Generates a detailed, digital record of every liquid handling step

- Aggregates and structures data from analytical devices, tying it back to the liquid handling records

It’s a lightning-fast process to go from designing to executing to analyzing. And if you’re onto a winner? Then, from the DOE, you have full knowledge of the complexities of the assay you’ve just optimized: ideal for method transfer into screening.

The Future of Assay Development

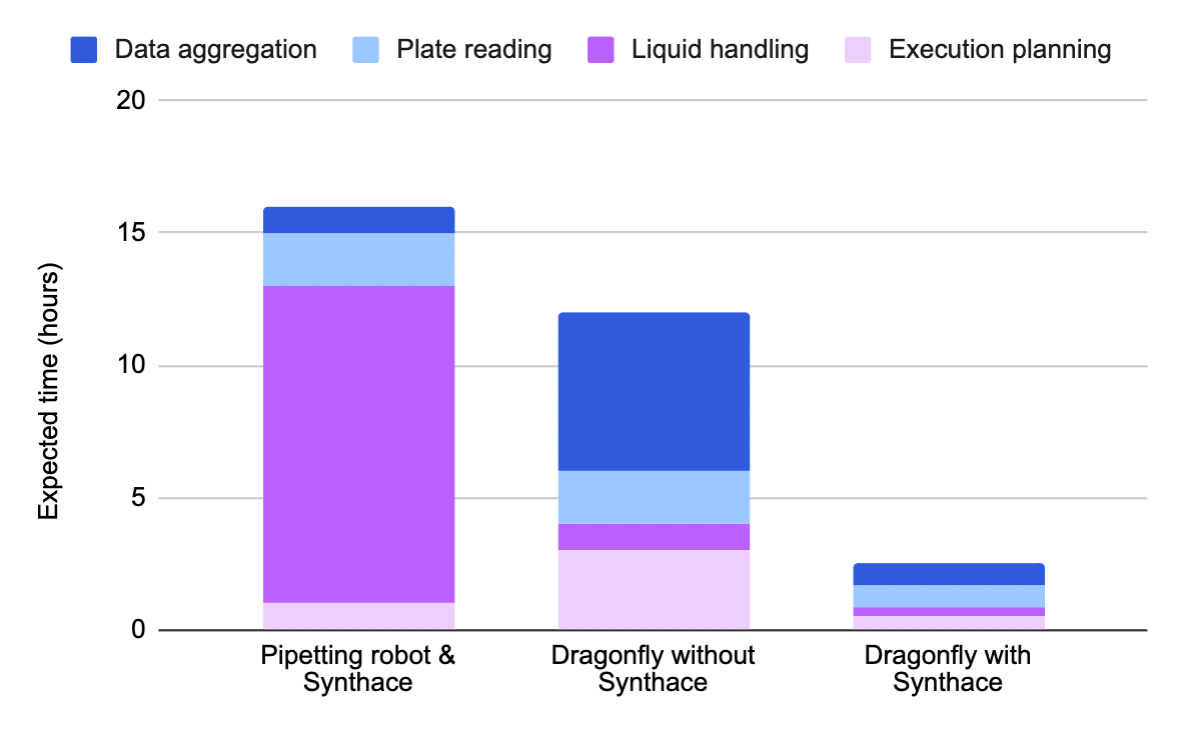

The combination of equipment like dragonfly and software like Synthace nets results that look like this:

- 75% faster execution planning

- 98% faster liquid handling

- 94% faster data structuring

- 87% overall time saving

And, compared to either working on their own, it’s clear that the sum is greater than the parts:

Not shown: manual pipetting (because it would take forever)

High throughput design of experiments done in this way would be a significant, powerful tool for any team. But what does this all mean for the future of assay development? Let’s go back to those two questions from the beginning of this article: how fast can we develop new assays, and how quickly can we transfer the winners into high throughput campaigns? With the right combination of hardware and software, the answer is clear: much faster than ever before.

If you’d like to go deeper on this topic, we’re running a joint webinar with SPT Labtech on April 27th at 3 pm BST/10 am EST. If you’re interested, you can sign up right here. If you can’t make it live, don’t worry: signing up through the link means you’ll get notified of where you can access the recording afterward.

See you there!

Other posts you might be interested in

View All PostsHow To Get Started With Design of Experiments

High Dimensional Experimentation: a new era for assay development

Implementing Design of Experiments (DOE): A practical example